WHAT IS METALCASTING?

Metalcasting is a scientific, engineering-reliant manufacturing process that produces metal components. It’s a $32 billion dollar industry that supports nearly everything we do, see and experience, from the cars we drive, to the lights in our ceilings, to the toilets we use.

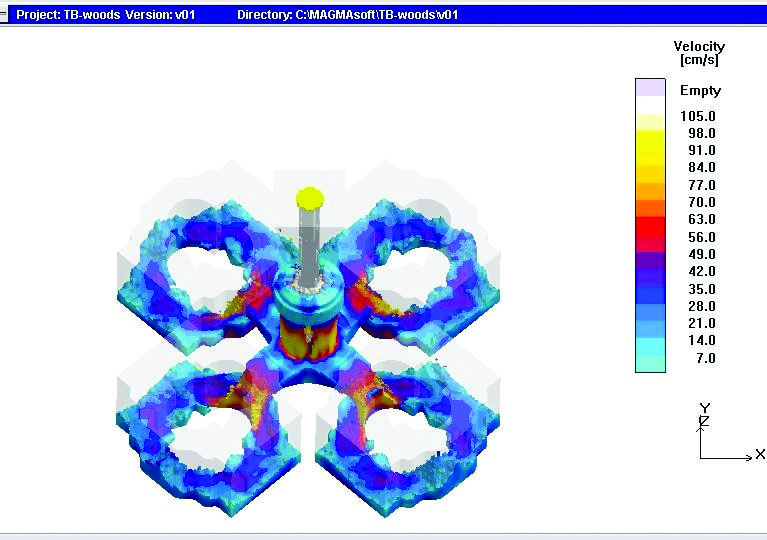

Metalcasting takes recycled metal, melts it to a liquid then pours it into a mold to form the shape of the final part. There are a lot of varieties and methods to doing this process, but that’s the barebones. Scientists are constantly dreaming up new ways to make castings better, faster and more economical. They’ve even found a way to put tiny particles of different materials into liquid metal to double the metal’s strength.

DEMOGRAPHICS

1,965: Number of metalcasting facilities in the U.S. In 1991 there were 3,200 plants and in 1955, 6,150 plants. 700 Ferrous; 1,300 Nonferrous

80%: Percentage of firms that are small businesses (less than 100 employees).

200,000+: Number of people employed by the U.S. metalcasting industry.

90% of all manufactured goods contain some metal castings.

The U.S. is the global leader in casting applications and second in production.

You are rarely more than 10 ft. from a metal casting in the United States.

HISTORY

1642: Year the Saugus Pot became the first casting produced on U.S. soil, near Lynn, MA.

7: Number of metalcasters that signed the Declaration of Independence: Philip Livingstone, George Taylor, James Smith, George Ross, Stephen Hopkins, Charles Carroll and James Wilson.

PRODUCTION AND APPLICATIONS

12 million: Total U.S. tonnage of castings produced in the U.S. in 2014

$32+ billion: Total value of all castings produced in the U.S. in 2014.